Looking for a flexible solution for metalworking in workshops and industry?

Industry specialist has an interesting new series in its portfolio: MEBAbase

And now brand new: MEBAbase 24 DG-HS

Do you work in a workshop, in mechanical engineering or in steel construction and need a steel saw that delivers good quality, doesn’t require any special features and works efficiently and reliably? Then you are no doubt familiar with the challenge of finding the right one in the jungle of machines on offer. You ask yourself the question: “Which metal band saw is the best?” Of course, there is no general answer to this and it depends on what you need. The fact is, however, that the new MEBAbase series from metal band saw professional MEBA could be the first choice for precisely this requirement. MEBAbase band saws are based on decades of expertise from the industry specialist, come with a good range of useful features as standard, you get top service for the machine, and best of all: all at a very good price. From DIY enthusiasts to professionals in the industry – the new MEBA series offers convincing solutions for many users.

Why a new series like MEBAbase?

While individual complete solutions, i.e. metal bandsawing machines with material handling and length measuring systems in all degrees of automation or even fully digitalized sawing systems that have to be precisely integrated into the company’s production planning are often required, there is also a desire for standardized individual saws. These should have good, sophisticated technology. However, individual additional options are not required. In other words, there is a desire for a simple, inexpensive metal band saw that is well equipped, delivers quality and works reliably.

MEBA is committed to developing benefit-oriented bandsaws for metalworking and listening to the market to find out exactly what users need. With the additional new product line, MEBA has responded to this wish. MEBAbase is a series that offers all the essentials: Reliable machines that are easy to operate and contain all the important functions for metalworking. It is ideal for anyone who needs a saw without a lot of bells and whistles, but with the certainty of getting good quality at a fair price. Small workshops have the opportunity to cut single pieces and small batches economically. Larger companies can also use these saws as an additional machine in series production and for large diameters, for example.

The best of both worlds: fast, online ordering

The MEBAbase series offers a wide range of machines, from manual mitre saws to double mitre saws, all of which cover the essentials for metalworking. The MEBAbase metal band saws are not produced by MEBA itself, but according to MEBA standards. The new product line was created as an extension of the MEBA product portfolio developed and manufactured in-house and is intended to offer customers a good alternative to customizable band saws. The quality requirements can be realized in this way and the customer receives the usual spare parts and band saw blade service from MEBA – “the best of both worlds”, so to speak. This is particularly advantageous when it comes to band saw blades, as the right band saw blade for the sawing task and material has a demonstrable effect on quality and performance and the machines are equipped with quality band saw blades from MEBA.

To summarize, the machines in the MEBAbase series could also be described as “starter saws”, with some models being interesting not only for the professional sector, but also for the ambitious hobby craftsman. MEBAbase machines can be ordered very easily from the company’s online store and do not have long delivery times. They do not require a great deal of advice. If questions do arise, the usual company service is available.

New model

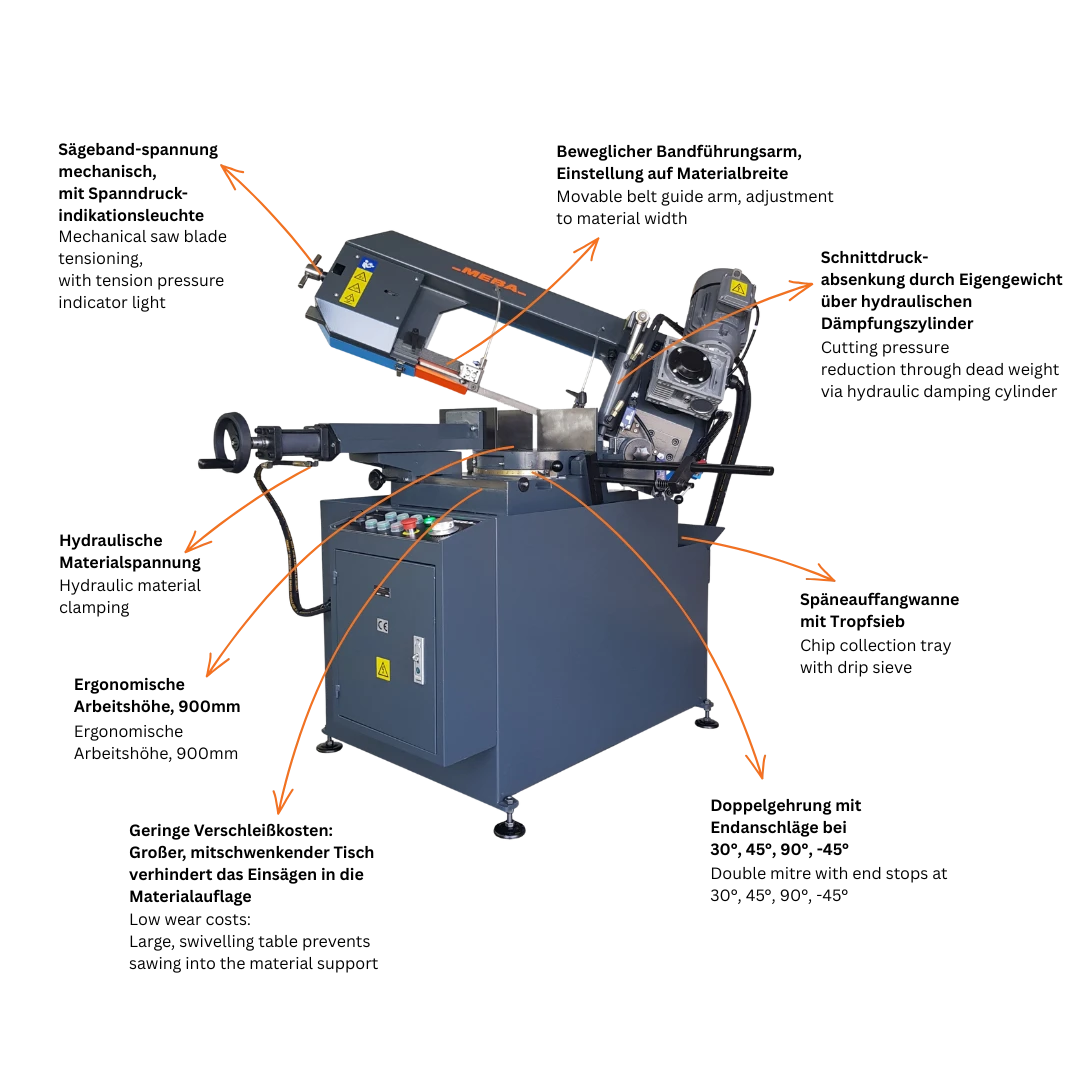

The newest member of the family is the MEBAbase 24 DG-HS. It is a true all-rounder. The mitre bandsaw for single cuts is designed for a cutting range of 310 mm width, 240 mm height and Ø 240 mm and comes with a good range of standard features, including virtually everything you need for a high cutting quality. This includes hydraulic material clamping, hydraulic lifting of the saw frame, good cutting speed of 35 + 75 m/min, ergonomic working height, manual mitre adjustment from 90° – 30° on a scale with 1.0° accuracy, cutting pressure reduction due to the weight of the heavy, torsion-resistant saw frame and fine adjustment as well as a range of accessories for chip removal and cleaning. These are just a few examples of the band saw’s excellent features. What is certainly one of the greatest quality factors of the base 24 DG-HS is the proven MEBA mitre system.

A large, pivoting table prevents sawing into the material support surface. What are the benefits? Above all, low wear costs. The material is always clamped at right angles close to the saw blade. Like all MEBA machines, the MEBAbase 24 DG is easy and convenient to operate, giving you great flexibility when deploying staff. The saw comes in a sturdy, solid design. A quality bi-metal saw blade is supplied already fitted. And finally, the small all-rounder can even be supplemented with a material roller conveyor in 1-meter increments, which was specially developed for this machine and, like the entire machine, can be ordered quickly and easily via the online store.

Who exactly is MEBAbase for?

The users of the MEBAbase series are as diverse as the machine models themselves. As already mentioned, the central feature of the band saws is the fact that all models are well equipped and sensibly configured out of the box. It doesn’t matter whether the production manager in mechanical engineering needs a machine for metalworking in a medium-sized company, the self-employed person is looking for workshop equipment for his metalworking shop, an industrial saw is to be purchased for training companies or as equipment for the commercial vocational school or there is a demand for a metal saw for steel fabricators. They all have one thing in common: they need a saw that meets their requirements simply, reliably and efficiently.

…and if you would like to know a little more about metal band saws in general…

What is metalworking?

Metalworking refers to all technical processes by which metals are processed, shaped or joined – whether by sawing or cutting, drilling, milling, welding or forming. The aim is to produce precise components or finished products from raw materials, which are used in almost all areas of industry. Sawing is one of the most basic tasks.

What can a metal band saw do?

The metal band sawing machine is a key tool in metal processing. It can be used to cut metal profiles, pipes or solid materials made of steel, stainless steel, aluminum, etc. efficiently and precisely. Thanks to the continuously running band saw blade, straight, clean cuts are also possible with different material thicknesses – a decisive advantage for precise and economical production processes. With a metal band saw, you can make straight cuts, mitre cuts or even cut complex shapes, depending on the model and equipment. The technology varies depending on the machine – from manual to automation and digitalization.

Which saw blade for the metal band saw?

The right saw blade is crucial for quality and efficiency. The choice depends on the material and thickness. At MEBA, you will find suitable saw blades that are perfectly matched to the MEBAbase machines. The MEBA saw blade expert is available for all machines and recommends saw blades that are individually tailored to the sawing task.

Leave A Comment