MAXIMIZE THE

PRODUCTIVITY WITH A

AUTOMATIC SAW FROM MEBA

MAXIMIZE PRODUCTIVITY WITH A SAWING MACHINE FROM MEBA

OUR AUTOMATIC SAWS OFFER THE HIGHEST LEVEL OF PRECISION AND EFFICIENCY,

WHEN IT COMES TO THE PROCESSING OF LARGE QUANTITIES OF CUT MATERIAL AT

AT THE SAME TIME, THE RESIDUAL QUANTITIES ARE KEPT TO A MINIMUM.

OUR AUTOMATIC SAWS OFFER THE HIGHEST DEGREE OF PRECISION AND EFFICIENCY WHEN IT COMES TO PROCESSING LARGE QUANTITIES OF CUT MATERIAL WHILE KEEPING RESIDUAL WASTE TO A MINIMUM.

In principle, automatic sawing machines can be used for all machinable materials. For details, please refer to the respective products that are suitable for your requirements. The principle of operation of an automatic band saw is always similar. Using a conveyor belt, you can precisely feed everything with the band saw as well as precisely define the cutting area that you want to saw. Depending on the model and year of manufacture, operation is made even easier by the possibility of networking and integrating CAD data and MEBAconnect.

AUTOMATIC BANDSAW WITH EXTENSIVE STANDARD EQUIPMENT WANTED?

In order for the machine to perform its tasks automatically, high-quality workmanship and flawless durability of all hydraulically and mechanically driven parts are necessary. Only then can you achieve high piece counts and good service lives for the saw bands. Our machines naturally offer these features in every version, preferably for use with certain machinable metals. Wood and plastic, on the other hand, are not the preferred applications for MEBA’s automatic saws.

An automatic saw increases your productivity through smooth processes and high efficiency in material consumption. If you choose one of our automatic bandsaws, you will most likely be able to significantly reduce your waste in residuals and offcuts compared to manual sawing. This is due, among other things, to the very precise and automatic adherence to the respective cutting range and maximum feed rate, so that residual lengths are very low. Such precision cannot be achieved manually – at least not with the same reliability in operation and accuracy in cutting.

Depending on the area of application, our automatic band saws have a variety of useful features and functions that can be adapted to your requirements.

PERFORMANCE

EXAMPLES OF THE PERFORMANCE OF

AUTOMATIC SAWS FROM OUR RANGE

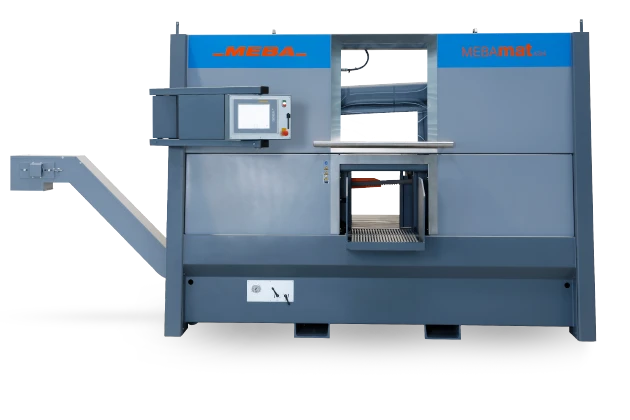

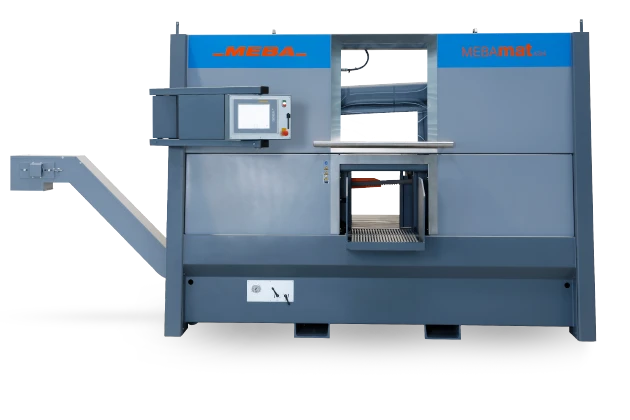

Our MEBAmat 434, for example, is a straight cut saw and designed as an automatic saw for serial cutting. With a maximum cutting range of 434 mm, the sawing machine covers a wide range of working possibilities. The closed design makes operation safer. At the same time, the accumulation of dirt and chips in the work area can be significantly reduced.

An ergonomic control on the panel is designed to be networkable and, if desired, can be configured with options for remote maintenance, for importing CAD files, and for creating individual saw programs and exporting them. An electric saw feed guarantees highest quality with simultaneous high performance during cutting and long service life of the band saw, as it is particularly protected.

PERFORMANCE

EXAMPLES OF THE PERFORMANCE OF AUTOMATIC SAWS FROM OUR PRODUCT RANGE

Our MEBAmat 434, for example, is a straight cut saw and designed as an automatic saw for serial cutting. With a maximum cutting range of 434 mm, the sawing machine covers a wide range of working possibilities. The closed design makes operation safer. At the same time, the accumulation of dirt and chips in the work area can be significantly reduced.

An ergonomic control on the panel is designed to be networkable and, if desired, can be configured with options for remote maintenance, for importing CAD files, and for creating individual saw programs and exporting them. An electric saw feed guarantees highest quality with simultaneous high performance during cutting and long service life of the band saw, as it is particularly protected.

MEBAMAT 330

The smaller brother of this automatic saw, the MEBAmat 330, also has impressive performance data. With a somewhat smaller cutting range, it is particularly suitable for smaller workpieces and production units that are to be machined in a limited space. At the same time, the saw is fully suitable for carbide and has a sophisticated ball screw drive with automatic feed monitoring and adjustment of the cutting pressure.

The hydraulic components for material tensioning are not only particularly precise, but also ensure constant maintenance of the saw band tension and perfect guidance during transport of the material. Cut tubes, profiles and solids from various materials in continuous operation. Ideal for production in the building trade, woodworking or even window manufacturing.

MEBAMAT 330

The smaller brother of this automatic saw, the MEBAmat 330, also has impressive performance data. With a somewhat smaller cutting range, it is particularly suitable for smaller workpieces and production units that are to be machined in a limited space. At the same time, the saw is fully suitable for carbide and has a sophisticated ball screw drive with automatic feed monitoring and adjustment of the cutting pressure.

The hydraulic components for material tensioning are not only particularly precise, but also ensure constant maintenance of the saw band tension and perfect guidance during transport of the material. Cut tubes, profiles and solids from various materials in continuous operation. Ideal for production in the building trade, woodworking or even window manufacturing.