THE METAL

BAND SAW

THE METAL BAND SAW

POWERFUL TOOL FOR

THE METALWORKING

POWERFUL TOOL FOR METALWORKING

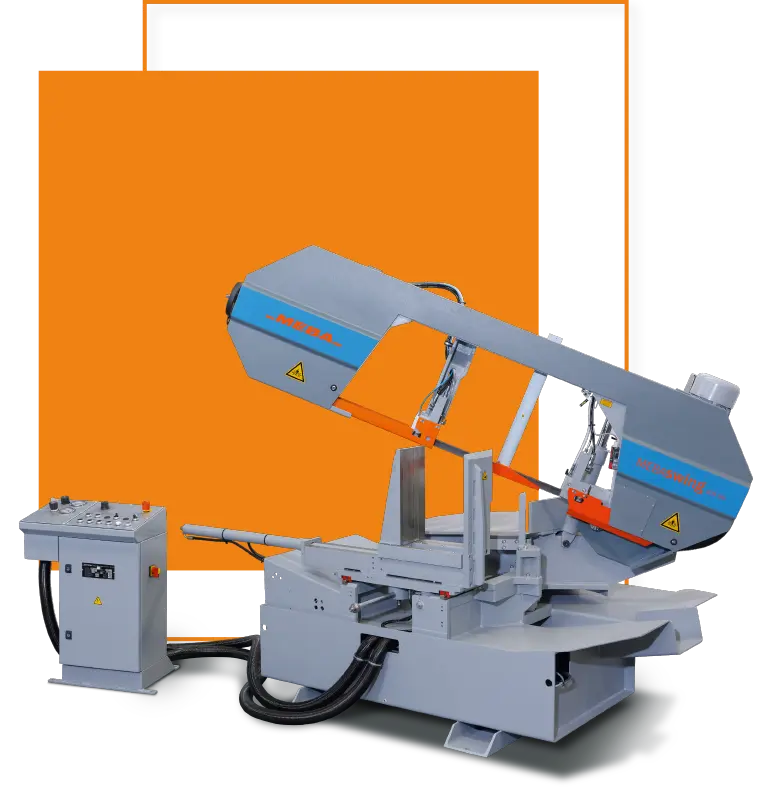

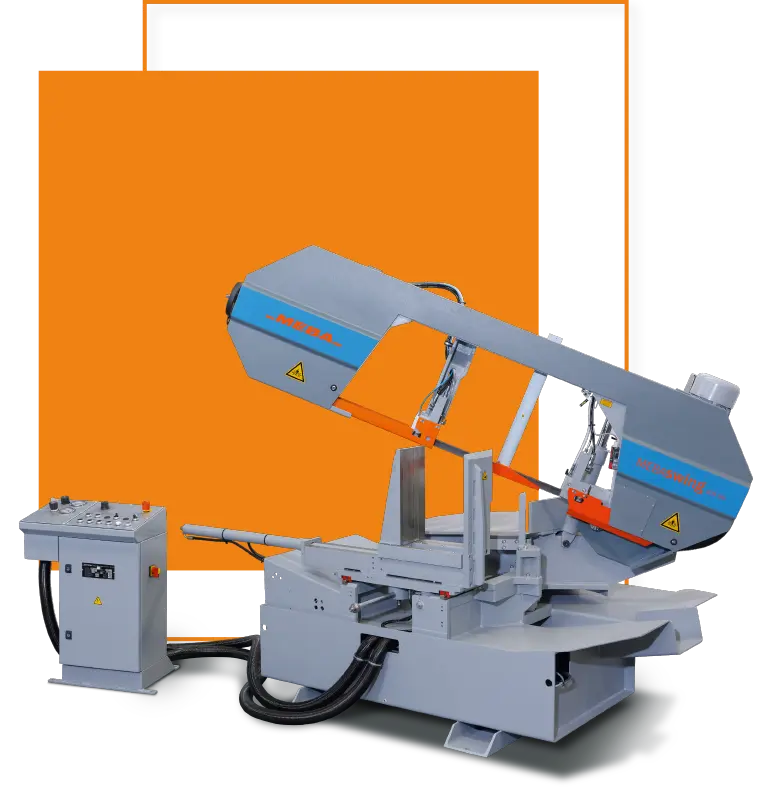

Although the classic band saw is used primarily in woodworking, it is at least as common in the metal cutting industry in the form of the metal band saw. Both band saws operate on the same principle, with a motor driving the deflection rollers for the saw band.

The distinctive feature of a band saw is the closed saw blade, which is usually set in motion vertically (but sometimes horizontally). The smooth movement makes the metal band saw one of the most precise machines in metalworking. The extremely precise cuts are in demand both in the trade and in large-scale production in industry and require a high-quality saw blade that meets the requirements of the material to be processed. Depending on this, a band saw differs in the number of teeth and the way they are interlocked.

Which saw blade is most suitable for your metal band saw also depends on whether you have automatic or manual cutting and how high the cutting speed is set. Depending on the manufacturer, the latter also influences the durability of the wear parts of your metal band saw, because incorrectly set speeds can lead to differences in the cutting pressure and the drive slip of the machine. Especially the wrong choice of speed often leads to premature wear on the components of a band saw.

VARIOUS DETAILS INFLUENCE THE FINAL RESULT

VARIOUS DETAILS INFLUENCE THE FINAL RESULT

METAL SAWS INDIVIDUALLY TAILORED TO YOUR NEEDS

METAL SAWS INDIVIDUALLY TAILORED TO YOUR NEEDS

The shape of the workpieces also influences the optimum choice of cutting power, because it makes a difference whether, for example, a square object or a round workpiece is to be cut. These and other factors ultimately influence the quality of the final result. So it is important to always choose the right accessories for your metal band saw and follow the manufacturer’s specifications,

that exist for the different materials.

In general, a band saw for metal processing can be used to process a wide variety of workpieces, including solid or hollow profiles, pipes, bars and other objects. The weight and size of the workpieces may be, of course, depends on the size and power of your metal band saw. The type of metals you can cut with the band saw is largely determined by the saw blade you use. For some materials a hardened saw band is recommended,

to get the optimum out of tool life and cutting performance.

The shape of the workpieces also influences the optimum choice of cutting power, because it makes a difference whether, for example, a square object or a round workpiece is to be cut. These and other factors ultimately influence the quality of the final result. So it is important to always choose the right accessories for your metal band saw and follow the manufacturer’s specifications that exist for the different materials.

In general, a band saw for metal processing can be used to process a wide variety of workpieces, including solid or hollow profiles, pipes, bars and other objects. The weight and size of the workpieces may be, of course, depends on the size and power of your metal band saw. The type of metals you can cut with the band saw is largely determined by the saw blade you use. For some materials, a hardened band saw blade is recommended to get the optimum of service life and cutting performance.

APPLICATION

APPLICATION

WHICH METALS CAN BE USED WITH THE

BAND SAW BE CUT?

WHAT METALS CAN BE CUT WITH THE BAND SAW?

In principle, with the right saw band you can process almost all so-called tough materials such as iron, copper, steel or even aluminum. It is not recommended to use a metal band saw for processing wood, as other saw blades are available for this purpose. Due to the frictional heat generated, metal band saws should not be run continuously for long periods of time.

Although several operations in succession are usually possible, the wear of the bands of a saw in continuous operation is significantly higher. However, depending on the manufacturer and the selected model, a band saw for metal can be additionally cooled. Nevertheless, the specifications of the manufacturer-specific load limits for the machine and saw band must be observed.

In our store you will find a wide range of suitable metal band saws including accessories and wear parts. For individual advice, please contact our technical staff. We will help you find the right band saw or the optimal saw blade for your requirements. Customized solutions are also possible thanks to our in-house saw blade production.