OUR SELECTION OF MACHINES

OUR SELECTION OF MACHINES

FROM SMALL TO LARGE, MANUAL OR FULLY AUTOMATIC – EVERYTHING FROM A SINGLE SOURCE

MEBA is there for everyone – whether small craft business or industry, you are guaranteed to find the right product exactly for your requirements in our portfolio. Regardless of whether you only need to saw parts now and then or permanently process orders in series. This is what we specialize in.

From the manual saw to the fully automatic sawing center with infeed and outfeed systems to the complex sawing plant, we offer an extensive range of high-quality, high-performance, robust and durable machines. Straight cut 90° or miter saws one-sided and two-sided, single or serial cuts, measuring systems and special solutions, at MEBA you get everything from one source. The individual components are perfectly matched to each other, so you always achieve outstanding results in the best quality.

MEBAeco

Individuality off the shelf

Our flagship in double miter technology. The MEBAeco series has proven itself for decades and has gone through numerous stages of development. Small, medium, large, 90 degrees, miter, double miter – everything is possible. From the semi-automatic straight cut saw to the fully automatic double miter saw with patented miter system. The MEBAeco series combines customer-specific requirements and the finest technology. We say to it: Individuality off the shelf. From our technically continuously developed modular system, you configure the optimum machine exactly for your needs: Metal construction, steel construction, industry or for special applications and solid materials.

The versatile automatic machines for serial cutting convince again and again with new features such as the trend-setting electric saw feed or state-of-the-art linear feed technology for all relevant guides. With its innovative functions, the MEBAeco offers the best prerequisites for digitizing your processes. Welcome to the future.

MEBAeco

Individuality off the shelf

Our flagship in double miter technology. The MEBAeco series has proven itself for decades and has gone through numerous stages of development. Small, medium, large, 90 degrees, miter, double miter – everything is possible. From the semi-automatic straight cut saw to the fully automatic double miter saw with patented miter system. The MEBAeco series combines customer-specific requirements and the finest technology. We say to it: Individuality off the shelf. You can configure the optimum machine exactly for your needs from our technically continuously developed modular system: Metal construction, steel construction, industry or for special applications and solid materials.

The versatile automatic machines for serial cutting convince again and again with new features such as the trend-setting electric saw feed or state-of-the-art linear feed technology for all relevant guides. With its innovative functions, the MEBAeco offers the best prerequisites for digitizing your processes. Welcome to the future.

MEBApro

YOUR ENTRY INTO AUTOMATION

Getting started with automation and Industry 4.0 has never been easier, even for smaller companies, than with MEBApro. With its compact design, the series offers high-tech in the smallest of spaces, ideal for machining in confined areas. This increases your productivity and reduces the cost per cut. More jobs in less time means higher profitability and efficiency in the sawing process. Semi-automatic or fully automatic, the MEBApro is unique in its class in terms of equipment and performance. As a straight-cutting saw or miter saw, the series reliably meets high demands on sawing technology. It is ideal for applications in a workshop, metalworking or railing construction, for example. In combination with MEBArobots, you can automate many work steps such as parts removal, cleaning and sorted depositing.

The highlight of the series is the combination of band saw MEBApro, drilling unit CreaDrill and an automatic length measuring system. The time-saving solution – here all functions are combined at one workstation: measuring, sawing, drilling. This is how we define modern manufacturing.

MEBApro

YOUR ENTRY INTO AUTOMATION

Getting started with automation and Industry 4.0 has never been easier, even for smaller companies, than with MEBApro. With its compact design, the series offers high-tech in the smallest of spaces, ideal for machining in confined areas. This increases your productivity and reduces the cost per cut. More jobs in less time means higher profitability and efficiency in the sawing process. Semi-automatic or fully automatic, the MEBApro is unique in its class in terms of equipment and performance. As a straight-cutting saw or miter saw, the series reliably meets high demands on sawing technology. It is ideal for applications in a workshop, metalworking or railing construction, for example. In combination with MEBArobots, you can automate many work steps such as parts removal, cleaning and sorted depositing.

The highlight of the series is the combination of band saw MEBApro, drilling unit CreaDrill and an automatic length measuring system. The time-saving solution – here all functions are combined at one workstation: measuring, sawing, drilling. This is how we define modern manufacturing.

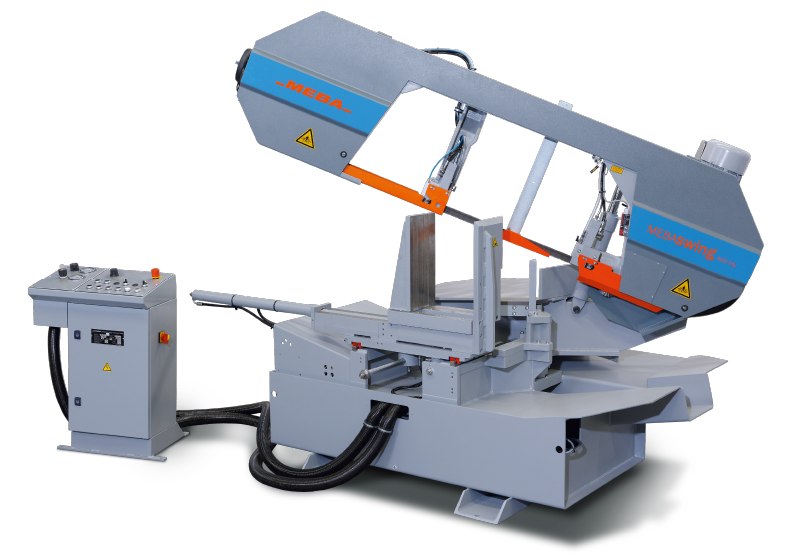

MEBAswing

ALLROUNDER FOR

DIVERSE APPLICATIONS

Set up, switch on, saw. This is how the metal bandsawing machines of the MEBAswing series can be described in a nutshell. The miter band saws with solid swivel bearing convince with easy handling, versatile application possibilities high precision and durability. Universally applicable, MEBAswing is the reliable helper for smaller workshops, in metalworking, window construction or railing construction. It is also suitable as a side saw for quick and clean cutting.

Versatility is the trump card: Different cross-sections, different materials or frequently changing miter cuts – MEBAswing is suitable for the most diverse applications. It is available as a well-proven miter machine, semi-automatic double miter machine or automatic bandsaw with NC control and electric material feed. An all-rounder, clever and uncomplicated.

MEBAswing

ALLROUNDER FOR

DIVERSE APPLICATIONS

Set up, switch on, saw. This is how the metal bandsawing machines of the MEBAswing series can be described in a nutshell. The miter band saws with solid swivel bearing convince with easy handling, versatile application possibilities high precision and durability. Universally applicable, MEBAswing is the reliable helper for smaller workshops, in metalworking, window construction or railing construction. It is also suitable as a side saw for quick and clean cutting.

Versatility is the trump card: Different cross-sections, different materials or frequently changing miter cuts – MEBAswing is suitable for the most diverse applications. It is available as a well-proven miter machine, semi-automatic double miter machine or automatic bandsaw with NC control and electric material feed. An all-rounder, clever and uncomplicated.

MEBAmat

Powerhouse for efficient production use

Our automated powerhouse for continuous use in single and multi-shift operation saws everything – from soft to extremely hard. MEBAmat means concentrated power for efficient production use in industry and the steel trade. Even solid materials made of difficult-to-cut materials are cut perfectly effortlessly by our straight-cut saw. Power, endurance, precision – these are the characteristics of our high-performance saws of the MEBAmat series.

With its continuous recirculating ball bearing guides on the material infeed and saw frame feed, the carbide-compatible automatic machine is smooth-running, low-maintenance and backlash-free. You expect a fast and precise saw cut? No problem thanks to powerful servo drive and ball screws at the material infeed as well as electric saw frame feed. Let yourself be inspired by the productivity, quality and user-friendliness of our power machine.

MEBAmat

Powerhouse for efficient production use

Our automated powerhouse for continuous use in single and multi-shift operation saws everything – from soft to extremely hard. MEBAmat means concentrated power for efficient production use in industry and the steel trade. Even solid materials made of difficult-to-cut materials are cut perfectly effortlessly by our straight-cut saw. Power, endurance, precision – these are the characteristics of our high-performance saws of the MEBAmat series.

With its continuous recirculating ball bearing guides at the material infeed and saw frame feed, the carbide-compatible automatic machine is smooth-running, low-maintenance and backlash-free. You expect a fast and precise saw cut? No problem thanks to powerful servo drive and ball screws at the material infeed as well as electric saw frame feed. Let yourself be inspired by the productivity, quality and user-friendliness of our power machine.

MEBAxtreme

Straight cut machine with the strong bite

Here the name says it all: MEBAxtreme is a machine for the really tough nuts in steel construction. You have extreme sawing tasks and expect superior cutting performance at the highest quality level – then the straight cutting machines from this series are exactly the right solution. It is not only the size of these semi- or fully automatic machines that is impressive, MEBAxtreme was developed for the very big tasks. Pure top performance when the going gets tough.

Despite their massive appearance and heavy construction, the automatic straight cutters are also model boys when it comes to energy and resource efficiency. The combination of reduced cutting channel, thin saw blade and high cutting speed increases productivity. The result is immense savings, especially when processing valuable materials or in the mass cutting area.

Whether solid materials or profiles, MEBAxtreme bites its way through.

MEBAxtreme

Straight cut machine with the strong bite

Here the name says it all: MEBAxtreme is a machine for the really tough nuts in steel construction. You have extreme sawing tasks and expect superior cutting performance at the highest quality level – then the straight cutting machines from this series are exactly the right solution. It is not only the size of these semi- or fully automatic machines that is impressive, MEBAxtreme was developed for the very big tasks. Pure top performance when the going gets tough.

Despite their massive appearance and heavy construction, the automatic straight cutters are also model boys when it comes to energy and resource efficiency. The combination of reduced cutting channel, thin saw blade and high cutting speed increases productivity. The result is immense savings, especially when processing valuable materials or in the mass cutting area. Whether solid materials or profiles, MEBAxtreme bites its way through.

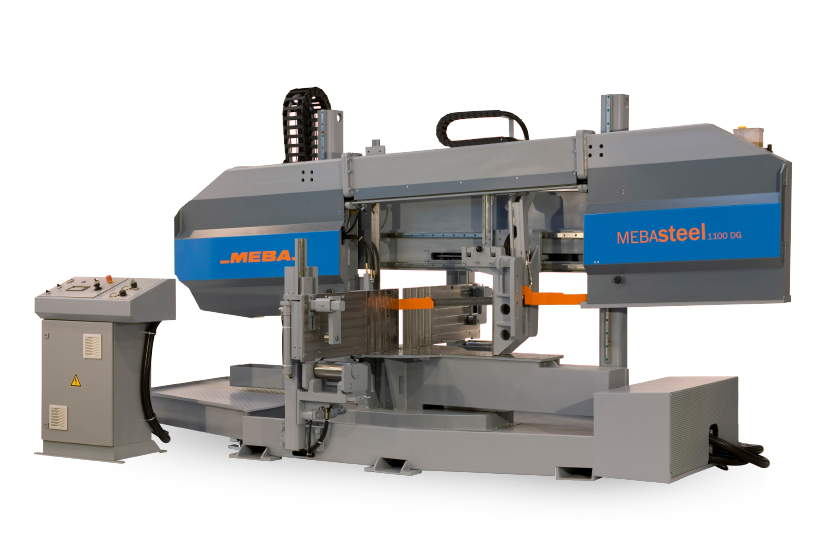

MEBAsteel

Unconditionally fast and maximally reliable

Big tasks are just her thing. The double miter bandsaws of the MEBAsteel series guarantee high productivity and process reliability through intelligent technology. Steel construction, bridge construction or high-rise building construction, MEBAsteel convinces even with challenging sawing requirements by highest cutting performance. Do not make any compromises: With these semi-automatic and fully automatic machines, you opt for the best double miter technology in the cutting range up to 1250 millimeters.

Sophisticated solutions, unconditionally fast and maximally reliable – whether different cross-sections, materials, frequently changing miter cuts or the heaviest materials. Solid materials and profiles as well as steel beams are sawn by MEBAsteel with the highest quality. The semi- and fully automatic machines with patented double miter technology solve all tasks powerfully, precisely and extremely economically.

MEBAsteel

Unconditionally fast and maximally reliable

Big tasks are just her thing. The double miter bandsaws of the MEBAsteel series guarantee high productivity and process reliability through intelligent technology. Steel construction, bridge construction or high-rise building construction, MEBAsteel convinces even with challenging sawing requirements by highest cutting performance. Do not make any compromises: With these semi-automatic and fully automatic machines, you opt for the best double miter technology in the cutting range up to 1250 millimeters.

Sophisticated solutions, unconditionally fast and maximally reliable – whether different cross-sections, materials, frequently changing miter cuts or the heaviest materials. Solid materials and profiles as well as steel beams are sawn by MEBAsteel with the highest quality. The semi-automatic and fully automatic machines with patented double miter technology solve all tasks powerfully, precisely and extremely economically.

LET US

ADVISE YOU

MEBArobots

FREEDOM FOR YOUR PROFESSIONALS

Relieve your employees from routine tasks and use these personnel resources elsewhere: MEBArobots automates many work steps around sawing. In this way, you improve the cost-effectiveness and efficiency of your processes. Specifically, a robot takes over activities such as cut-off handling, post-processing, quality assurance and quality control. Take advantage of this potential of MEBArobots and meet the growing shortage of skilled workers in a targeted manner. A real added value that gives you a clear competitive advantage in the market environment.

MEBArobots

FREEDOM FOR YOUR PROFESSIONALS

Relieve your employees from routine tasks and use these personnel resources elsewhere: MEBArobots automates many work steps around sawing. In this way, you improve the cost-effectiveness and efficiency of your processes. Specifically, a robot takes over activities such as cut-off handling, post-processing, quality assurance and quality control. Take advantage of this potential of MEBArobots and meet the growing shortage of skilled workers in a targeted manner. A real added value that gives you a clear competitive advantage in the market environment.

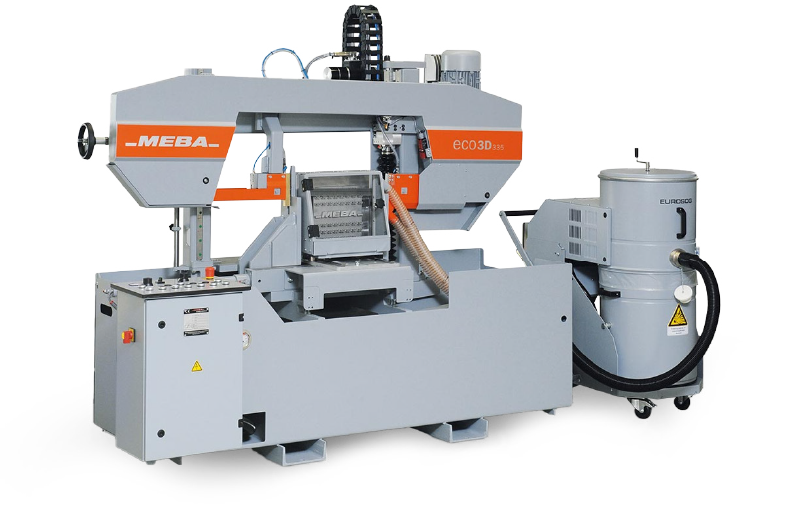

MEBA3D

The fast and cost-effective solution for removing 3D printed parts from the base plate

Additive manufacturing is becoming increasingly important in metal processing. Part of this process is the separation of 3D printed parts from the base plate. Well before 3D sawing became a trend, MEBA developed a concept for this that has a fast process time and very good cutting results with low operating and cost requirements at the same time: MEBA3D 335 / 510.

The MEBA concept is based on the straight-cut saws of the successful MEBAeco product family. They stand for state-of-the-art machine technology, high efficiency and best cutting results. The metal band saw machine is equipped with a special clamping device to hold build-up plates and can precisely release 3D printed workpieces on the customer’s own build-up plate.

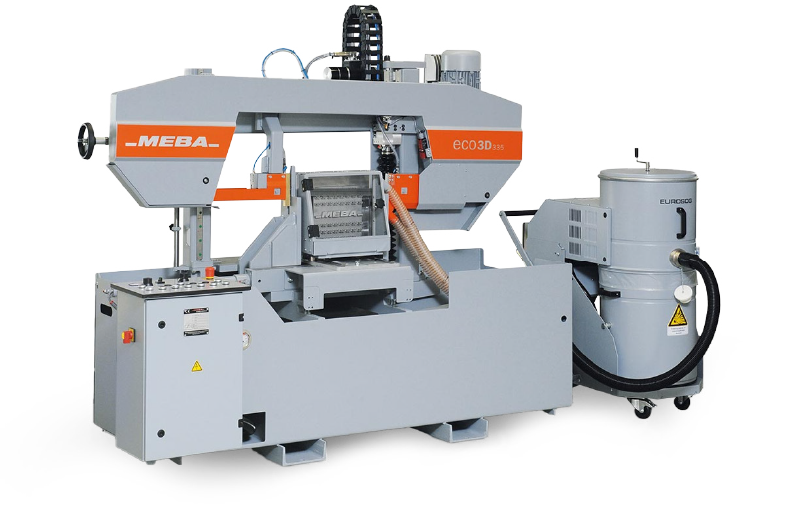

MEBA3D

The fast and cost-effective solution for removing 3D printed parts from the base plate

Additive manufacturing is becoming increasingly important in metal processing. Part of this process is the separation of 3D printed parts from the base plate. Well before 3D sawing became a trend, MEBA developed a concept for this that has a fast process time and very good cutting results with low operating and cost requirements at the same time: MEBA3D 335 / 510.

The MEBA concept is based on the straight-cut saws of the successful MEBAeco product family. They stand for state-of-the-art machine technology, high efficiency and best cutting results. The metal band saw machine is equipped with a special clamping device to hold build-up plates and can precisely release 3D printed workpieces on the customer’s own build-up plate.