MEBA3D

MEBA3D

Separate 3D parts cleanly and efficiently

from the base plate

Separate 3D parts from the base plate cleanly and efficiently

In the field of additive manufacturing, MEBA is an innovation driver in the post-processing of products from the 3D printer. Long before 3D sawing became a trend, we developed a concept and practical solutions to cleanly and precisely separate 3D printed parts from the base plate. The advantages are obvious: fast process times, very good cutting results, low operating and cost requirements. With the MEBA3D models you are again the decisive step ahead. One of our many enthusiastic customers puts it in a nutshell: “The additively manufactured components can be cleanly separated from the base plate with the MEBA bandsaw. Neither components nor base plate are damaged. We are very satisfied with the results.”

Special clamping device

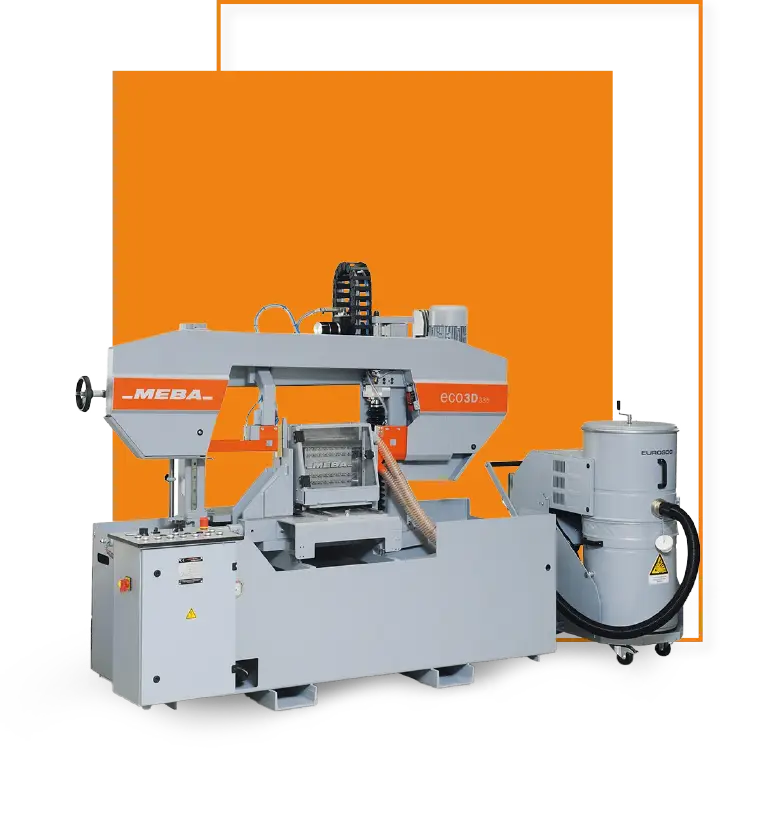

3D metal printing has become increasingly important in recent years. Our concept for finishing is based on the straight cut saws of the successful MEBAeco product family, which stands for state-of-the-art machine technology, high efficiency and best cutting results.

Our MEBA3D has a special clamping device for holding the build-up plates. You can align them so precisely that the band saw accurately releases the 3D printed workpieces from your build plate. Cutting channel and feed monitoring ensure high process reliability. Optionally, a protective housing and an additional suction device prevent dust from spreading during machining.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information3D sawing machine: MEBAeco3D for additive manufacturing

The 3D sawing machine for additive manufacturing MEBAeco3D. The metal saw for cutting 3D printed parts from build plates, as a perfect complement for additive manufacturing.

User friendly application

In particular, the user-friendly application is a big plus of our 3D sawing concept compared to conventional processes such as

Wire EDM.

You clamp the build-up plate and start the sawing process. In addition to significantly lower purchase and maintenance costs, the long service life of the saw band keeps your costs down. And you can increase the utilization and amortization of the machine without much effort: In just a few steps, you can convert the MEBA3D for standard sawing jobs.

You already have a MEBA bandsaw in use and would like to use the advanced 3D system? In many cases, the machine can be upgraded easily and cost-effectively.

User friendly application

In particular, the user-friendly application is a major plus of our 3D sawing concept compared to conventional processes such as wire EDM.

You clamp the build-up plate and start the sawing process. In addition to significantly lower purchase and maintenance costs, the long service life of the saw band keeps your costs down. And you can increase the utilization and amortization of the machine without much effort: In just a few steps, you can convert the MEBA3D for standard sawing jobs.

You already have a MEBA bandsaw in use and would like to use the advanced 3D system? In many cases, the machine can be upgraded easily and cost-effectively.

Saw including clamping device

Saw including clamping device

Clamping device for precise cutting of 3D printed workpieces

Our metal band saw machine is equipped with a special clamping device to hold build-up plates and can accurately release 3D printed workpieces from the customer’s own build-up plate. They fix the plate on the MEBA fixture, which can be moved as required via linear guides and thus aligned precisely.

At the end of the sawing process, you disassemble the jig plate and can use it for further printing with little rework. Our MEBA3D gently detaches 3D parts from the plate with little effort and a fast saw cut.

Option hood

Option hood

Hood for 3D package

Your advantages

Option industrial vacuum cleaner

Option industrial vacuum cleaner

Industrial vacuum cleaner for 3D package

Your advantages

Important safety note

Dust explosion-proof industrial vacuum cleaners are not suitable from a safety point of view for sucking up or extracting explosive substances or equivalent substances within the meaning of §1 SprengG (German Explosives Act), liquids and mixtures of combustible dusts with liquids. The operator guarantees safe avoidance of ignition sources.

YOUR ADVANTAGES

Compared to conventional production methods such as wire EDM, the MEBA 3D sawing concept is extremely uncomplicated with only a few operating steps: simply clamp and saw. The acquisition and maintenance costs are significantly lower.

The long service life of the saw band also keeps costs low. Utilization and amortization of the saw are additionally favored by the fact that MEBA3D saws can also be used for standard sawing jobs with little conversion effort.

MEBA3d in its

process chain

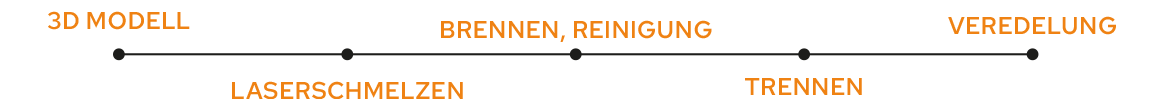

MEBA3d in your process chain

The process

The 3D parts are printed onto a plate. You fix this plate on the MEBA fixture, which you can move as you wish via linear guides and thus align precisely. Once the plate is aligned, the sawing process begins. MEBA3D band saws remove the 3D printed workpieces quickly and accurately from the plate. These fall down and can be removed, if necessary further refined. At the end of the sawing process, disassemble the fixture plate and use it for further printing with little rework. With little effort and a quick saw cut, you have gently released the 3D parts from the plate.

MEBAtipp

You already work with a MEBA saw and now you want to enjoy the advantages of 3D sawing without buying a new machine right away? Contact us:

We will be happy to check whether the MEBA3D system is also compatible with your saw. The entire device is built on a base plate and can be mounted on some MEBA models. 3D sawing therefore does not automatically require the purchase of a completely new saw, but can in many cases be easily and cost-effectively added to your existing machinery.

You have the task –

we have the solution!

Our experts will advise you individually.

MEBAtipp

You already work with a MEBA saw and now you want to enjoy the advantages of 3D sawing without buying a new machine right away? Contact us:

We will be happy to check whether the MEBA3D system is also compatible with your saw. The entire device is built on a base plate and can be mounted on some MEBA models. 3D sawing therefore does not automatically require the purchase of a completely new saw, but can in many cases be easily and cost-effectively added to your existing machinery.

You have the task – we have the solution!

Our experts will advise you individually.